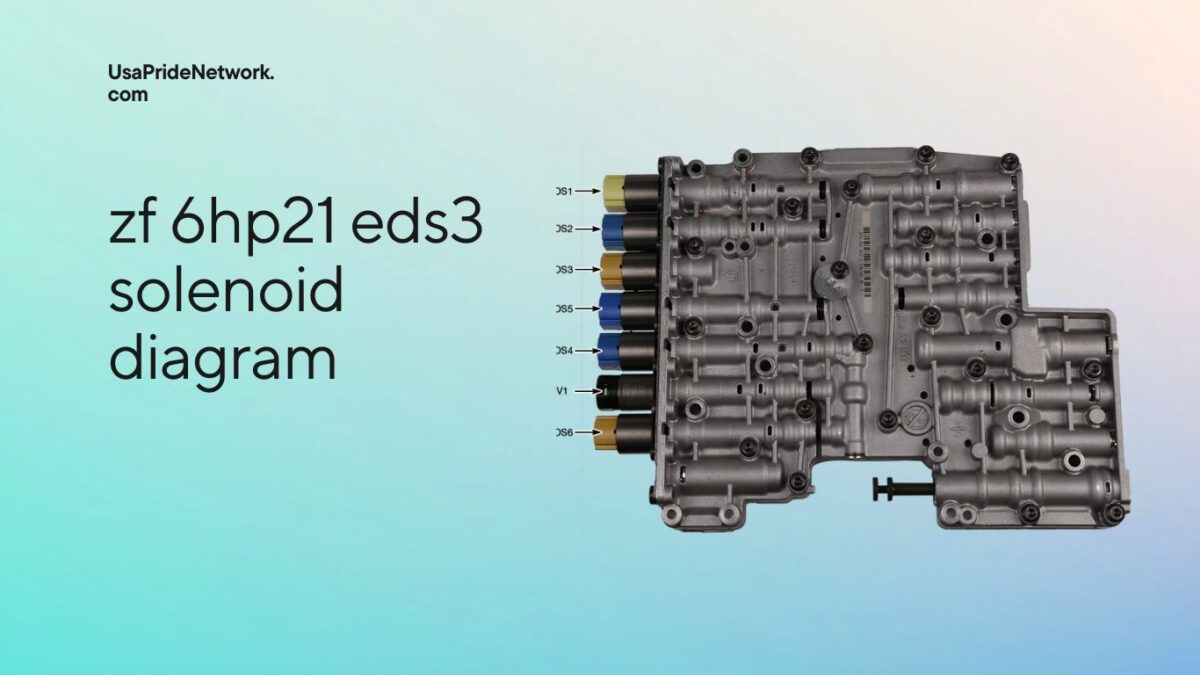

The ZF 6HP21 EDS3 solenoid diagram helps diagnose and maintain smooth transmission operation by mapping solenoid locations, connections, and hydraulic flow.

This guide provides a detailed overview of the ZF 6HP21 EDS3 solenoid diagram, covering its components, functions, and troubleshooting tips. Designed for mechanics and car enthusiasts, it offers clear, practical insights for maintaining smooth transmission performance.

What is the ZF 6HP21 Transmission?

The ZF 6HP21 is a six-speed automatic transmission used in various vehicles, including BMW, Audi, Jaguar, and Land Rover. Known for its efficiency and smooth shifting, it incorporates advanced mechatronics (a combination of mechanics and electronics) to optimize performance.

The EDS3 solenoid is one of the essential components in this transmission. It regulates hydraulic pressure to control gear shifts, ensuring smooth and precise operation. The solenoid diagram visually maps the arrangement of solenoids, valves, and associated components, making it a valuable tool for troubleshooting.

Understanding the ZF 6HP21 EDS3 Solenoid Diagram

The solenoid diagram illustrates the placement and function of each solenoid within the transmission. For the EDS3 solenoid, the diagram provides insights into:

- Location: The EDS3 solenoid is typically situated on the valve body, controlling a specific hydraulic circuit.

- O-Ring Placement: O-rings ensure a tight seal between solenoids and the valve body to prevent fluid leaks.

- Connections: Electrical connectors link the solenoid to the transmission control module (TCM), enabling communication.

- Fluid Flow: The diagram shows how hydraulic fluid flows through the solenoid to facilitate gear changes.

Key Components Highlighted in the Diagram:

- EDS (Electro-hydraulic Solenoids): EDS3 is part of a series (EDS1–EDS6) that manage pressure control for various gears.

- Mechatronic Unit: Houses the solenoids and integrates electronic controls with hydraulic systems.

- Valve Body: The core of the transmission where solenoids and valves are mounted.

How Does the EDS3 Solenoid Work?

The EDS3 solenoid operates as a pressure control valve. Here’s a simplified explanation of its functionality:

- Signal Reception: The TCM sends electrical signals to the EDS3 solenoid.

- Hydraulic Adjustment: Based on the signal, the solenoid adjusts hydraulic pressure.

- Gear Engagement: The adjusted pressure allows the transmission to engage the appropriate gear.

This process happens in milliseconds, ensuring seamless gear transitions and optimal performance.

Common Issues with the ZF 6HP21 EDS3 Solenoid

Despite its reliability, the EDS3 solenoid can encounter problems over time. Here are the most common issues:

1. Fluid Leaks

- Cause: Worn or damaged O-rings.

- Symptom: Transmission fluid leaks, leading to low fluid levels and erratic gear shifts.

- Solution: Replace the O-rings as shown in the solenoid diagram.

2. Electrical Failures

- Cause: Faulty wiring or corroded connectors.

- Symptom: The TCM fails to communicate with the solenoid, causing transmission errors.

- Solution: Inspect and repair the electrical connections.

3. Contamination

- Cause: Dirt and debris in the transmission fluid.

- Symptom: Solenoid blockage, resulting in harsh or delayed shifting.

- Solution: Flush the transmission and replace the fluid.

4. Wear and Tear

- Cause: Prolonged use or overheating.

- Symptom: Reduced solenoid performance, leading to slipping gears.

- Solution: Replace the EDS3 solenoid.

Troubleshooting the EDS3 Solenoid Using the Diagram

The ZF 6HP21 EDS3 solenoid diagram is an essential tool for diagnosing issues. Here’s how to use it effectively:

- Identify the EDS3 Solenoid: Locate it on the valve body using the diagram.

- Inspect O-Rings: Check the diagram for O-ring placements and verify their condition.

- Test Electrical Signals: Use a multimeter to ensure proper voltage and continuity to the EDS3 solenoid.

- Check Fluid Flow: Refer to the diagram to confirm unobstructed hydraulic paths.

Step-by-Step Guide to Replacing the EDS3 Solenoid

If the solenoid is damaged, follow these steps to replace it:

- Gather Tools:

- Socket set

- Screwdrivers

- O-ring kit

- Transmission fluid

- Drain Transmission Fluid:

- Remove the transmission pan to access the solenoids.

- Locate EDS3 Solenoid:

- Refer to the solenoid diagram for its exact position.

- Remove the Solenoid:

- Disconnect the electrical connector and unbolt the solenoid.

- Install the New Solenoid:

- Replace O-rings and secure the new solenoid in place.

- Reassemble and Refill:

- Reattach the transmission pan and refill with fluid.

- Test Drive:

- Verify proper operation through a road test.

Preventive Maintenance Tips for the ZF 6HP21 Transmission

- Regular Fluid Changes: Use high-quality transmission fluid and replace it every 60,000 miles.

- Inspect O-Rings: Check for wear during routine maintenance.

- Clean the Mechatronics Unit: Prevent debris from clogging solenoids.

- Monitor Electrical Connections: Ensure connectors remain corrosion-free.

FAQs

1. What is the purpose of the EDS3 solenoid?

The EDS3 solenoid regulates hydraulic pressure for specific gear functions in the ZF 6HP21 transmission.

2. Where can I find the ZF 6HP21 EDS3 solenoid diagram?

The diagram is typically included in the transmission service manual or available through specialized automotive repair platforms.

3. What are the symptoms of a faulty EDS3 solenoid?

Common symptoms include erratic shifting, delayed gear engagement, and transmission error codes.

4. Can I replace the EDS3 solenoid myself?

Yes, with the right tools and knowledge of the solenoid diagram, you can replace it. However, professional assistance is recommended for complex issues.

5. How much does it cost to replace the EDS3 solenoid?

The cost ranges from $150 to $400, depending on labor and parts.

By thoroughly understanding the ZF 6HP21 EDS3 solenoid diagram, you can effectively diagnose and repair issues, ensuring your vehicle’s transmission operates at peak performance. Regular maintenance and a proactive approach to troubleshooting will keep this advanced system running smoothly for years to come.